Preface:

Apparently they are still “a thing”. The reasons I’m writing this are:

1. I still find I’m being asked about them.

2. Since TalkTalk ceased their user webpages service, this information has nowhere to live … until now.

A long time ago I used to work in a local cinema as a film projectionist. When cinemas had film. I don’t know if it was peculiar to the site where I worked, but I was expected to be the “fix everything” person. So this included a set of moving message LED signs imported from somewhere. Over some years I identified some problems which happened time and time again. I had a summary of the information I knew, with information I had gathered from other sources. I reproduce that information here, as it still seems to be useful to some people.

I note that the manufacturer is still trading, but the products listed here are considered obsolete.

What follows is more-or-less a copy-and-paste, with some minor edits to remove dead links.

I was asked to repair a “faulty” electronic sign. When connected to the power, it would boot correctly with version information e.t.c. Immediately it would then freeze, with gibberish in the display.

I reasoned (guessed really) the sign’s internal, battery-backed RAM, was corrupt and causing the sign’s OS to crash. The external keypad was being ignored.

This could apply to so many models of electronic signs produced by various companies, the sign I repaired is model FS-W2002DCA. Due to the economies of scale, a single control PCB is manufactured and populated with different RAM chips, and different EEPROMs to make the different signs in the range:

FS-W1002DR

FS-W1002DH

FS-W1002LR

FS-W1002LH

FS-W1002LC

FS-W1502DR

FS-W1502DH

FS-W1502LR

FS-W1502LH

FS-W1502LC

FS-W1502DCA

FS-W1504DR

FS-W1504DH

FS-W1504LR

FS-W1504LH

FS-W1504LC

FS-W2002DR

FS-W2002DH

FS-W2002LR

FS-W2002LH

FS-W2002LC

FS-W2002DCA

FS-W2004DR

FS-W2004DH

FS-W2004LR

FS-W2004LH

FS-W2004LC

Of course, the above list is for the benefit of anyone using a search engine.

The repair works by removing the RAM from the battery back-up. Really what you are doing is giving the sign a factory reset.

Remove one of the end caps of the case, remove rear panels until you can get to the central control circuit board. If there are lots of socketed ICs, you’re in luck. Remove them all, making sure you take note of their position and orientation. Take your time with this part of the task.

Replace all the ICs in the correct sockets, and re-assemble the sign.

The sign should now work correctly. If it doesn’t, it was beyond repair before you started.

Other information:

Since I created this page, I’ve been contacted by others who have encountered these signs. They have provided me with some other information about these signs. To quote part of one email from one of them:

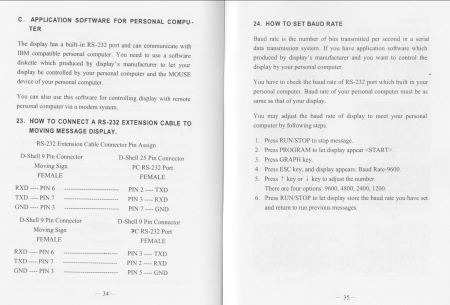

I managed to get hold of a keyboard for the display (on loan), but what I have discovered is that it does not communicate via RS232, much to my frustration…. because the plug on the back of the display is not standard 232, other pins are sent to the keyboard (TTL level). I can now set the clock with the keyboard, but I still cannot set it via the PC. The keyboard sends something other than RS232 signals, it looks like 8 bits similar to 9600 baud, but is not standard i.e. pressing “1” followed by “2”, does not produce a 1 bit change. There is also a bit allocated to wether the key is pressed or released.

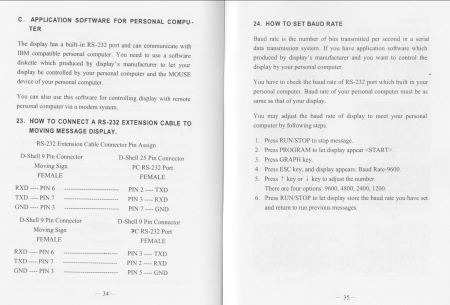

I have also been given this URL: http://www.fspring.com.tw/fspring/pages/downloads.htm which (see comments for an alternative link) seems to be software to control the signs from a PC via a serial port. I went back to the manual and scanned a couple of pages:

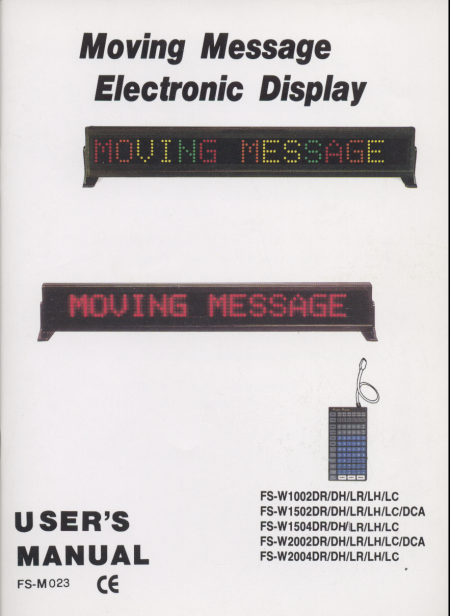

Front cover

How to make an RS232 adapter (actually useful!)

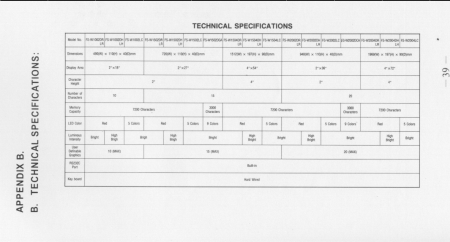

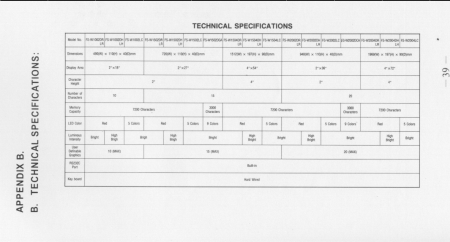

Features of the various models of sign

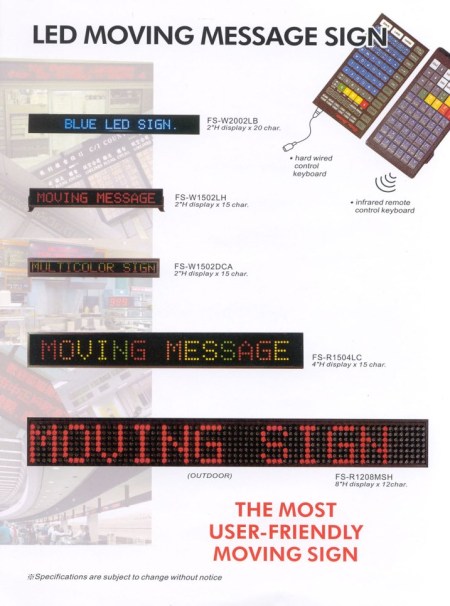

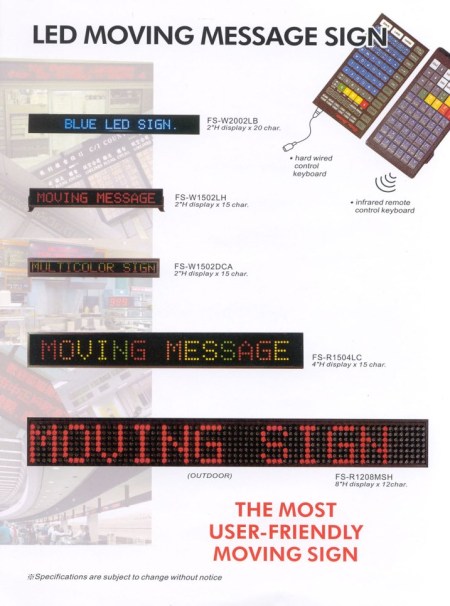

This is an image I didn’t scan, but it seems to be of a publicity flyer for some of the signs in their range, including some signs not listed above.

In case that page referenced above moves, you can download the PC control software and manual from here (edit: see below). The manual is in Word format, and OpenOffice 2.0 opens it without fuss.

SSign_MANUAL

Alternative link

I’ve not tested the control software, and I probably will not be able to do so in the near future.

Repairing the keypad and its cable.

After a while the keypad will stop working, this is likely to be either the 9 way D type connector being worn, or the cable being worn. It’s not a standard RS232 cable for two reasons: (a) there are power connections on pin 8 and 9 and (b) the Rx and Tx lines are not on pins 2 and 3.

It is a simple task to replace the plug (and cable), and I hope you find this drawing helpful.

PinOutElectronicSign

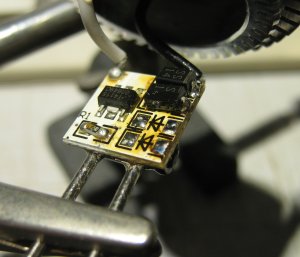

Repairing the connector on the back of the electronic sign.

You might observe, after a lot of useage, that the 9 way D-type plug becomes loose on the PCB within. This is because there’s no strain relief on the plug body. Equip yourself with a straight-PCB-mount 9W D plug (RS components part number 472-758). You’ll need to disassemble the entire case, including all those small black screws from the various back panels.

The main control board can be readily unplugged from the display panels, and it’s easier to work on that way.